What Makes CVD TaC Coated Three-Petal Guide Rings Unique in High-Performance Applications?

2025-01-14

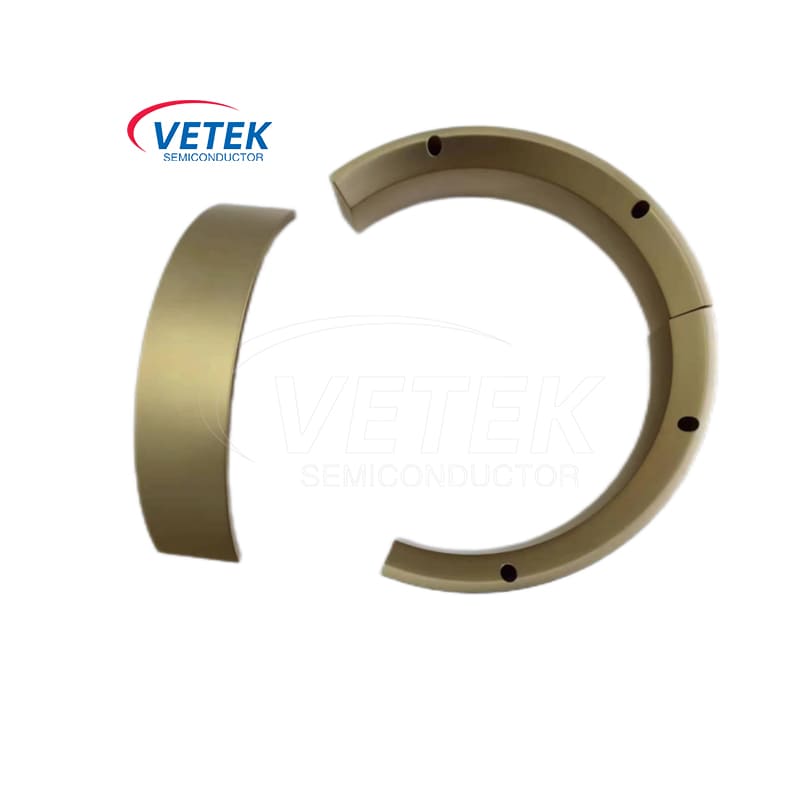

In industries requiring precision and durability, components like the CVD TaC (Tantalum Carbide) coated three-petal guide ring play a critical role. These specialized parts are used in high-temperature, high-wear environments, offering unparalleled performance where traditional materials fail. But what exactly makes these guide rings unique, and why are they increasingly sought after?

1. What is a CVD TaC Coated Three-Petal Guide Ring?

The three-petal guide ring is a precision-engineered component designed for guiding, supporting, or stabilizing systems that operate under extreme conditions. The CVD (Chemical Vapor Deposition) coating of Tantalum Carbide adds a protective layer, enhancing the ring's physical and chemical properties.

2. Key Features of the CVD TaC Coating

- Exceptional Hardness: Tantalum Carbide ranks among the hardest materials, providing superior wear resistance.

- High-Temperature Stability: The coating maintains its integrity at temperatures exceeding 4000°F (2200°C), making it ideal for extreme environments.

- Corrosion Resistance: TaC is highly resistant to chemical degradation, including exposure to acids and alkalis.

- Low Friction Coefficient: Reduces wear and tear in moving parts, ensuring smooth operation.

3. Applications of Three-Petal Guide Rings

The CVD TaC coated guide rings are commonly used in:

- Aerospace: In propulsion systems and high-temperature mechanisms.

- Metal Processing: For guiding molten metal and high-temperature rolls.

- Semiconductor Industry: As precision parts in deposition chambers.

- Power Generation: In turbines and reactors that demand robust components.

4. Advantages Over Traditional Materials

- Enhanced Durability: The TaC coating significantly increases the lifespan of the guide ring.

- Improved Precision: Low friction and high dimensional stability ensure accurate performance.

- Reduced Maintenance: Less wear and corrosion mean fewer replacements and lower downtime.

- Versatility: Suitable for a wide range of industries and challenging applications.

5. Why Choose CVD Coating for Guide Rings?

CVD technology ensures uniform, high-purity coatings with excellent adhesion. This makes the TaC layer not just a surface treatment but an integral part of the component, capable of withstanding prolonged stress and extreme conditions.

The CVD TaC coated three-petal guide ring is a marvel of modern engineering, designed to meet the demands of the most challenging applications. Its combination of durability, precision, and resistance to extreme conditions makes it an invaluable component in industries where performance cannot be compromised.