Unveiling the Applications: Materials Suited for Diamond Wheels Brushed Bronze

2024-03-21

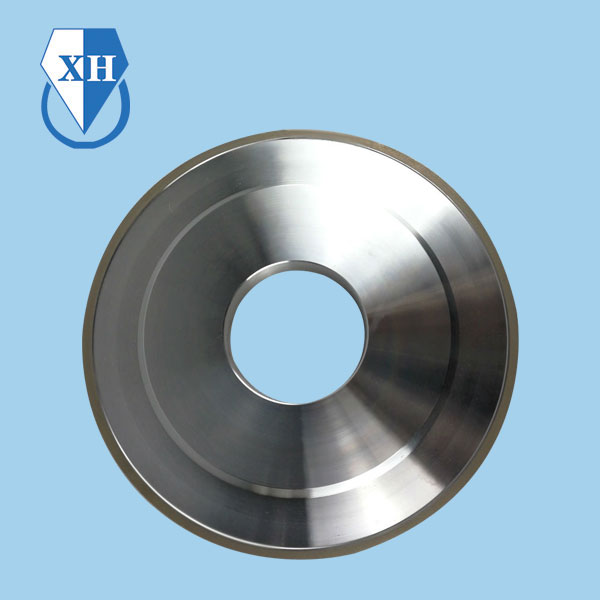

In the realm of precision machining and surface finishing, the choice of tools plays a critical role in achieving exceptional results. Diamond wheels brushed bronze represent a sophisticated approach to material removal and surface treatment, offering unparalleled performance and aesthetics. These specialized tools are particularly well-suited for a variety of materials across different industries. Let's explore the materials that diamond wheels brushed bronze are typically used for and the advantages they offer in each application.

1. Metal Alloys:

Diamond wheels brushed bronze are commonly employed in machining various metal alloys, including aluminum, brass, bronze, copper, and titanium. These materials often require precision machining to achieve fine surface finishes and intricate geometries. Diamond wheels offer superior hardness and cutting efficiency, making them ideal for shaping, grinding, and polishing metal components with precision and accuracy.

2. Ceramics:

Ceramic materials, known for their hardness, abrasion resistance, and thermal stability, pose unique challenges in machining and surface finishing. Diamond wheels brushed bronze are well-suited for grinding and polishing ceramic components used in industries such as aerospace, electronics, and medical devices. The exceptional hardness of diamond particles enables precise material removal and fine surface finishes on ceramic substrates.

3. Glass:

Glass is another material that benefits from the precision and efficiency of diamond wheels brushed bronze. From optical lenses and electronic displays to architectural glass and decorative items, diamond wheels are used to shape, grind, and polish glass components with exceptional clarity and smoothness. The bronze brushing process adds a unique aesthetic dimension to glass surfaces, enhancing their visual appeal.

4. Composite Materials:

Composite materials, such as carbon fiber reinforced polymers (CFRP) and fiberglass, are increasingly used in aerospace, automotive, and wind energy applications due to their lightweight and high-strength properties. Diamond wheels brushed bronze are well-suited for machining composite materials, offering precise material removal and fine surface finishes while minimizing delamination and fiber pullout.

5. Precious Metals and Jewelry:

In the realm of jewelry manufacturing and precious metal fabrication, diamond wheels brushed bronze play a crucial role in shaping, grinding, and polishing precious metals such as gold, silver, platinum, and palladium. These materials require meticulous attention to detail and superior surface finishes to achieve the desired aesthetic and value. Diamond wheels offer the precision and finesse required for crafting exquisite jewelry and luxury goods.

6. Hardened Steels and Tool Steels:

Diamond wheels brushed bronze are also used for machining hardened steels and tool steels commonly employed in tool and die making, mold manufacturing, and automotive components. These materials require abrasive tools capable of withstanding high cutting forces and maintaining sharpness and precision over extended machining operations. Diamond wheels offer exceptional hardness and wear resistance, making them well-suited for grinding and shaping hardened steel components.

7. Advanced Engineering Materials:

In addition to the aforementioned materials, diamond wheels brushed bronze find applications in machining advanced engineering materials such as high-performance plastics, ceramics, composites, and superalloys used in aerospace, defense, and medical industries. These materials often exhibit challenging machining characteristics, requiring specialized abrasive tools capable of delivering precise and consistent results.

In conclusion, diamond wheels brushed bronze are versatile tools capable of machining a wide range of materials across various industries. From metals and ceramics to glass and composites, these specialized abrasive tools offer exceptional hardness, precision, and aesthetics, making them indispensable for achieving superior surface finishes and dimensional accuracy in precision machining applications. By harnessing the capabilities of diamond wheels brushed bronze, manufacturers can elevate the quality and performance of their machined components across diverse material substrates.