Understanding the Purpose of Guide Pins and Bushings in a Press Die Mold

2024-05-31

In the world of precision metalworking and stamping, press die molds are the unsung heroes behind countless manufactured products. These intricate tools require a careful balance of strength, durability, and precision to ensure consistent and accurate results. Among the various components that make up a press die mold, guide pins and bushings play a crucial role in ensuring the smooth and precise operation of the mold. Let's delve into the purpose and significance of these components.

What Are Guide Pins and Bushings?

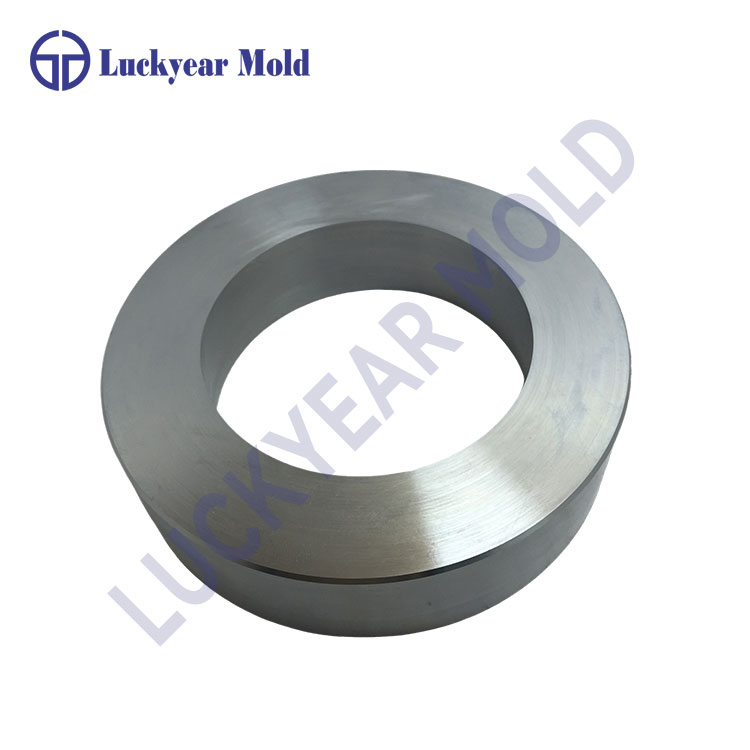

Guide pins and bushings are precision-made components that work in tandem to guide and align the moving parts of a press die mold. The guide pins, typically made of hardened steel, protrude from one half of the mold and fit into precision-machined bushings in the other half. This arrangement ensures that the two halves of the mold align precisely when they come together during the stamping process.

The Purpose of Guide Pins and Bushings

Alignment and Positioning: The primary purpose of guide pins and bushings is to ensure that the two halves of the mold align precisely when they come together. This alignment is crucial for maintaining the accuracy of the stamped parts and preventing damage to the mold or machinery.

Stability and Rigidity: By providing a rigid connection between the mold halves, guide pins and bushings help to stabilize the mold during the stamping process. This stability reduces the chances of vibration or misalignment, which can lead to defects in the stamped parts.

Ease of Assembly and Disassembly: Well-designed guide pins and bushings make it easier to assemble and disassemble the mold. This facilitates maintenance, repair, and the replacement of worn-out components, extending the mold's lifespan and reducing downtime.

Wear Resistance: Guide pins and bushings are typically made of wear-resistant materials such as hardened steel. This ensures that they can withstand the repeated impacts and friction that occur during the stamping process, maintaining their precision and performance over time.

Considerations for Guide Pins and Bushings

When selecting or designing guide pins and bushings for a press die mold, it's essential to consider factors such as the material being stamped, the size and complexity of the parts, and the speed and frequency of the stamping process. The guide pins and bushings must be able to handle the forces and pressures involved while maintaining precision and durability.

Conclusion

In conclusion, guide pins and bushings play a vital role in ensuring the smooth and precise operation of a press die mold. Their ability to provide alignment, stability, ease of assembly, and wear resistance makes them indispensable components of any stamping operation. By understanding their purpose and significance, manufacturers can ensure that their press die molds perform optimally and produce consistent, high-quality stamped parts.