Step-by-Step Guide: Conducting a Test with the Fire Hazard Testing Apparatus Glow Wire Tester

2024-07-03

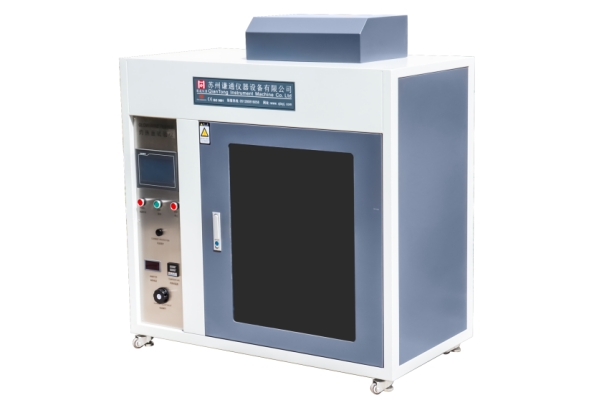

Ensuring the safety of materials and products against fire hazards is critical in various industries. The Fire Hazard Testing Apparatus glow wire tester is a specialized device used to evaluate the fire resistance of materials when exposed to high temperatures. In this blog, we will explain the operational procedure for conducting a test with this apparatus, providing a comprehensive step-by-step guide.

Understanding the Glow Wire Test

The glow wire test is designed to simulate the effects of thermal stress that materials might encounter in real-world scenarios, particularly those involving electrical components. The test involves heating a metal wire to a specific temperature and applying it to the material under test (MUT) to observe its reaction, such as ignition, flame spread, or self-extinguishing properties.

Step-by-Step Testing Procedure

1. Preparing the Test Apparatus

1. Calibrate the Apparatus: Ensure that the glow wire tester is calibrated according to the manufacturer’s specifications. This includes verifying the temperature settings and ensuring the accuracy of the heating elements.

2. Clean the Glow Wire: Clean the glow wire to remove any residues from previous tests. This can be done using a suitable cleaning agent and a soft cloth.

2. Preparing the Test Specimen

1. Select the Material: Choose the material or product to be tested. Ensure it meets the dimensions and specifications required for the glow wire test.

2. Condition the Specimen: Condition the test specimen according to the relevant standards. This typically involves maintaining the specimen at a specified temperature and humidity for a set period.

3. Mount the Specimen: Securely mount the test specimen on the apparatus. Ensure that it is positioned correctly and that there is no movement during the test.

3. Setting Up the Test Parameters

1. Set the Temperature: Adjust the glow wire temperature according to the test requirements. Common test temperatures range from 550°C to 960°C, depending on the standards being followed.

2. Adjust the Application Force: Set the force with which the glow wire will be applied to the test specimen. This is typically done using a spring mechanism or a calibrated weight.

4. Conducting the Test

1. Heating the Glow Wire: Activate the heating element to heat the glow wire to the predetermined temperature. Allow it to stabilize at the required temperature for a few minutes.

2. Applying the Glow Wire: Apply the heated glow wire to the test specimen with the specified force. The contact time is usually set for 30 seconds unless specified otherwise by the test standard.

3. Observing the Reaction: Carefully observe the reaction of the test specimen during and after the application of the glow wire. Note any ignition, flame spread, or self-extinguishing behavior.

5. Recording the Results

1. Document Observations: Record all observations made during the test, including the time to ignition, duration of burning, and whether the material self-extinguished.

2. Measure Flame Length: If applicable, measure the length of any flames produced during the test.

3. Note Residual Effects: After removing the glow wire, document any residual glowing or smoldering of the test specimen.

Safety Considerations

- Personal Protective Equipment (PPE): Always wear appropriate PPE, such as heat-resistant gloves, safety goggles, and lab coats, to protect against burns and other hazards.

- Ventilation: Ensure adequate ventilation in the testing area to safely dissipate any smoke or fumes produced during the test.

- Emergency Procedures: Familiarize yourself with emergency procedures, including the location of fire extinguishers and emergency exits.

Conclusion

The Fire Hazard Testing Apparatus glow wire tester is a crucial tool for assessing the fire resistance of materials and products. By following the detailed step-by-step procedure outlined above, you can ensure accurate and reliable test results. Proper preparation, careful observation, and meticulous recording of results are key to understanding how materials respond to thermal stress and ensuring their safety in real-world applications.