Minimizing Harmful Emissions: How Environmental Friendly Waste Incinerators Work

2024-06-27

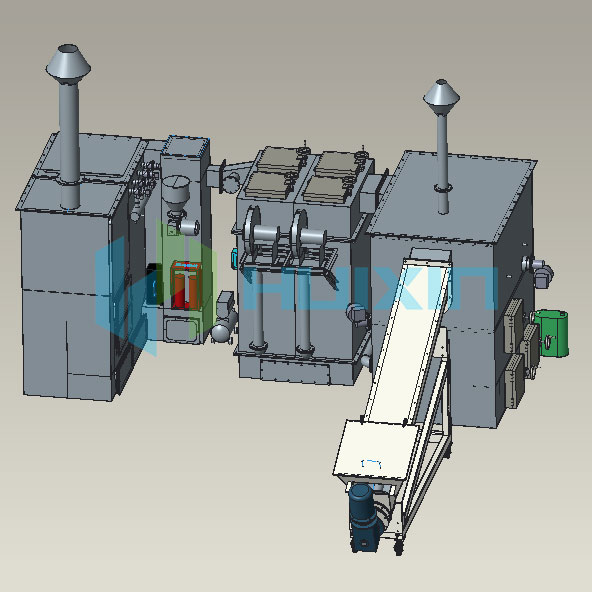

In the quest for sustainable waste management, Environmental Friendly Waste Incinerators (EFWIs) stand out as a significant innovation. Traditional waste incineration methods have long been criticized for their contribution to air pollution and harmful emissions. However, EFWIs are designed to address these environmental concerns through advanced technologies and processes. In this blog, we will explore how an Environmental Friendly Waste Incinerator minimizes harmful emissions and pollutants during the waste incineration process.

1. Advanced Combustion Techniques

One of the fundamental ways EFWIs minimize harmful emissions is through the use of advanced combustion techniques.

- High-Temperature Combustion: EFWIs operate at higher temperatures compared to traditional incinerators. High temperatures ensure more complete combustion of waste materials, reducing the production of harmful by-products such as carbon monoxide (CO) and volatile organic compounds (VOCs).

- Optimized Airflow: These incinerators are equipped with sophisticated systems to control and optimize airflow, ensuring that the combustion process is efficient and that fuel is completely burned. This minimizes the formation of soot and other particulate matter.

2. Emission Control Systems

EFWIs are equipped with multiple layers of emission control systems designed to capture and neutralize harmful pollutants before they are released into the atmosphere.

- Scrubbers: Wet and dry scrubbers are used to remove acidic gases, such as sulfur dioxide (SO2) and hydrogen chloride (HCl), from the flue gas. These devices use a liquid or solid reagent to neutralize acidic compounds.

- Electrostatic Precipitators (ESPs): ESPs are used to capture fine particulate matter from the flue gas. By applying an electric charge to the particles, ESPs cause them to clump together and be removed from the gas stream.

- Fabric Filters: Also known as baghouses, these filters trap particulate matter using a series of fabric bags that act as a barrier, preventing particles from escaping into the atmosphere.

3. Catalytic Converters

Catalytic converters play a crucial role in reducing emissions of harmful gases such as nitrogen oxides (NOx) and carbon monoxide (CO).

- Selective Catalytic Reduction (SCR): This process involves injecting a reagent, typically ammonia or urea, into the flue gas. The gas then passes through a catalyst that promotes a chemical reaction, converting NOx into harmless nitrogen (N2) and water (H2O).

- Oxidation Catalysts: These catalysts facilitate the oxidation of CO and VOCs into carbon dioxide (CO2) and water, significantly reducing the emission of these harmful gases.

4. Continuous Emission Monitoring

Continuous Emission Monitoring Systems (CEMS) are essential for ensuring that EFWIs operate within regulatory limits and maintain minimal emissions.

- Real-Time Data: CEMS provide real-time data on the levels of various pollutants in the flue gas. This allows operators to make immediate adjustments to the incineration process if any emissions approach regulatory limits.

- Automated Controls: Automated control systems use data from CEMS to dynamically adjust operational parameters, such as temperature and reagent injection rates, optimizing the combustion process and emission controls.

5. Carbon Capture and Storage (CCS)

Some EFWIs incorporate Carbon Capture and Storage (CCS) technology to further reduce their environmental impact.

- Carbon Capture: This involves capturing CO2 emissions from the flue gas using chemical solvents, physical adsorption, or membrane separation technologies.

- Storage: The captured CO2 is then transported and stored underground in geological formations, preventing it from entering the atmosphere and contributing to climate change.

6. Use of Renewable Energy Sources

Integrating renewable energy sources with EFWIs can further enhance their environmental performance.

- Solar and Wind Power: Using renewable energy sources to power the incineration plant reduces reliance on fossil fuels, decreasing the overall carbon footprint of the waste management process.

- Energy Recovery: EFWIs are designed to recover energy from the waste incineration process. This energy can be converted into electricity or used for heating, reducing the need for external energy sources and promoting a circular economy.

Conclusion

Environmental Friendly Waste Incinerators represent a significant advancement in waste management technology. By incorporating advanced combustion techniques, sophisticated emission control systems, catalytic converters, continuous emission monitoring, carbon capture and storage, and renewable energy sources, these incinerators effectively minimize harmful emissions and pollutants. As we strive for more sustainable waste management solutions, the adoption of EFWIs offers a promising path towards reducing the environmental impact of waste incineration and protecting public health.